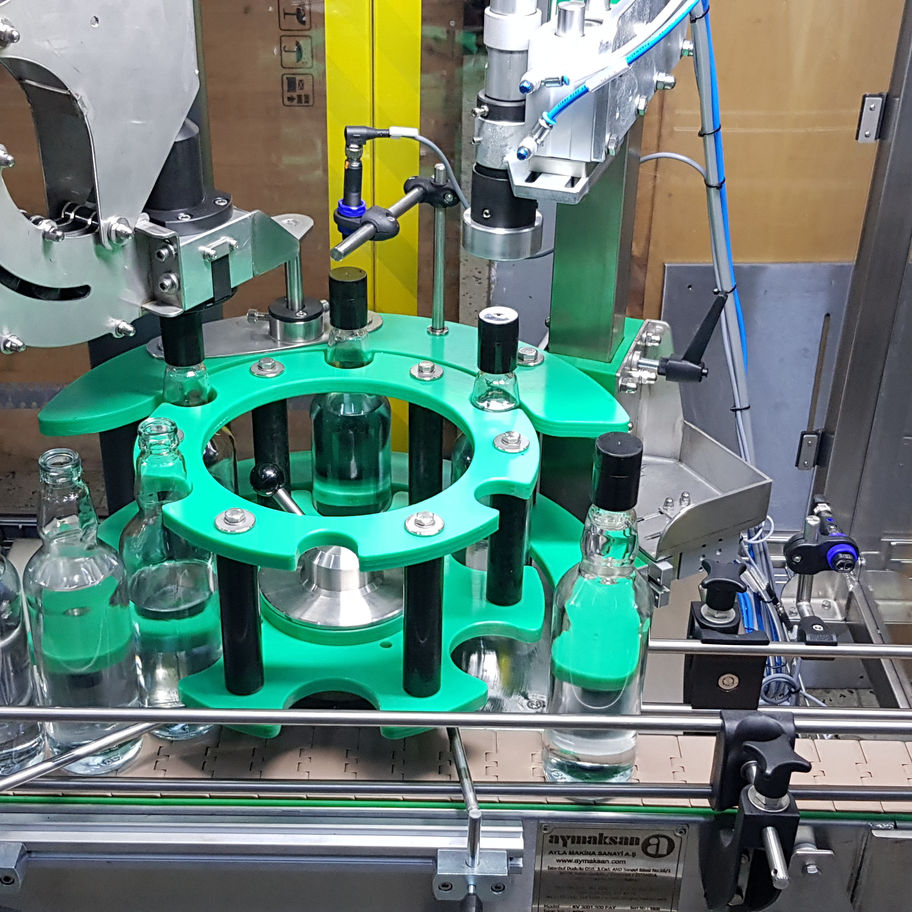

Volumetric Filling Line AF2

The automatic filling line with a linear conveyor is designed for the precise and standardized filling and capping of products with varying viscosities using a volumetric system. The key components of the primary packaging line include a Rotary Package Feeding Table, a Bottle Dry Cleaning Machine, a Volumetric Filling Machine, a Screw & Press-On Capping Machine, an Induction Foil Sealing Machine, a Wrap-Around Labeling Machine, and a Rotary Package Collection Table. The line can be configured to operate from left to right or right to left based on the factory's workflow and to maximize space efficiency. It is designed to maintain capacity and performance without compromise. The filling line is equipped with various machines that provide efficient solutions for filling, capping, and labeling operations, and all operational parameters are configured to meet the requirements of the product, cap, and package to be used.

Adjustable Quantity and Speed

Easily adjustable filling volumes and product filling & package transfer speed settings provide repeatable precision and high-performance filling operations.

Flexible Settings for Various Packages

The machine adapts to different package formats quickly and effortlessly with minimal tooling requirements.

Quick and Easy Cleaning

Areas in contact with the product can be rapidly cleaned without disassembling filling line components.

Operation in Wet Environments

It operates smoothly even in wet conditions, ensuring reliable performance.

CE Certification Compliance

The machine is manufactured in full compliance with CE certification standards.

User-Friendly Automation

All functions are easily controlled via an intuitive HMI panel, enhancing ease of use.

Streamlined Design

The machine's design allows for simple adjustments, enabling format changes without the need for highly skilled operators.

Reliable Spare Parts Support

Standardized and readily available spare parts ensure smooth and long-lasting operation for many years.