Chemical Processing Vessels and Other Structures From Stainless Steel.

Custom Solutions to

Your Industrial Processing Needs

Custom Solutions to

Your Industrial Processing Needs

Chemical Processing Vessels and Other Structures From Stainless Steel.

About Ceytas

Ceytas is driven by quality, trust, and innovation, powered by a skilled team of 27 professionals. They have been serving global industry leaders since 1992.

Ceytaş provides sustainable fabrication services for leading companies in the energy, food, chemical, mineral, plastic, glass, recycling, and paper industries worldwide.

They specialize in process design, automation, and manufacturing high-quality equipment — including vacuum sterilizers, vacuum fumigation chamber, heat exchangers, vacuum evaporators, mixers, tanks, reactors, and vessels — tailored to each client’s requirements, budget, and expectations. Trusted worldwide, they deliver reliable industrial equipment and plant project solutions.

Professional, Custom Services:

Turnkey Projects

Engineering

Installation

Support

EXPERTISE IN

CHEMICAL

PRODUCTION

They offer comprehensive solutions for various chemical industries, including pharmaceuticals, fertilizers, and specialty chemicals.

- Custom design and engineering

- Detailed flow diagrams and TNIDs

- State-of-the-art production lines

- Installation and commissioning

- Compliance with industry standards

FOOD INDUSTRY

EQUIPMENT

MANUFACTURING

Their expertise extends to the food industry, where they provide robust and efficient machinery for:

- Food processing and handling

- Beverage production

- Dairy and bakery equipment

- Custom solutions for unique food production needs

CUSTOM DESIGN

&

MANUFACTURING

They specialize in custom machine and equipment design:

- A team of expert engineers and craftsmen

- Creating innovative solutions using a wide range of high-quality materials, including stainless steel and mild steel

- From concept to manufacturing, they ensure every project meets the highest standards

CUSTOM BUILT - TANKS, REACTORS & AGITATORS

They offer new custom-built stainless steel storage tanks, mixing tanks, and pressure tanks from 50L to 100,000L, configured and produced based on customer requirements.

All tanks can be equipped with heat exchangers, insulation, and various agitators from different suppliers.

The following codes and general standards apply to their atmospheric tanks:

-

EN13920 – Construction standard for storage tanks

-

ISO 13920:1996 – Tolerances for welding constructions

-

EN1672-2/2005+A/2009 – Equipment for food preparation and processing

-

EN10088:2005 – General standard for stainless steel

-

DIN EN ISO 3834-2 – Fusion welding certification

-

Internal protocols for visual, non-destructive, and hydrostatic testing

-

Certification for quality management

-

WPQR (LMK) (QMOS)

-

WPS EN ISO 15614-1

-

Certification for welding operators EN ISO 9606-1

-

Certification for material 3.1

Additional codes and general standards for pressure tanks:

-

PED CE declaration of conformity

-

EN13445-3 – Construction and calculation standard

-

X-ray monitoring

-

ISO 9001:2008 traceability

-

Risk analysis

Additional codes and general standards for mixing tanks:

-

CE declaration of conformity in accordance with directive 2006/42/EC

-

ISO 9001:2008 traceability

-

Risk analysis

Each tank from their inventory can be adapted quickly. Tanks can be fitted with agitators, insulation, various connections, and more. Customers can choose from their large inventory, and the workshop team will make the required adjustments. A 3D technical drawing is prepared, and modifications are planned together with the customer. Adjustments can be made to both new and second-hand tanks in stock.

They also offer custom-built agitators, which can be purchased separately for existing tanks, with ATEX agitator options available.

PLANT AUTOMATION & CONTROL

Embrace the future of manufacturing with our advanced plant automation and control solutions. We integrate the latest technologies to enhance efficiency and productivity:

Programmable Logic Controllers (PLCs): Our PLC systems ensure precise control and monitoring of your production processes, improving reliability and reducing downtime.

Supervisory Control and Data Acquisition (SCADA): SCADA systems provide real-time data acquisition and control, enabling you to monitor and optimize your operations seamlessly.

Human-Machine Interfaces (HMIs): User-friendly HMIs facilitate easy interaction between operators and machinery, enhancing operational efficiency.

POWDER & LIQUID

FERTILIZER

PRODUCTION LINEs

Ceytaş excels in designing and manufacturing state-of-the-art stainless steel production lines for both powder and liquid fertilizers. Their advanced systems are tailored to meet the stringent requirements of the fertilizer industry, ensuring efficient, reliable, and high-quality production processes. From initial consultation to final installation, their expertise guarantees that each production line is optimized for peak performance and durability.

PROCESS TANKS

Tanks for All Applications and Industries

They provide custom tanks, vessels, and reactors designed with clients, considering:

-

Powder/liquid mixing

-

Pressure or vacuum operation

-

Heating and cooling

-

Hygiene and cleanability

They guide nozzle and connector selection, optimize spray ball placement, and ensure the right surface finish. From mobile stainless steel vessels for pharmaceuticals to CCT tanks for breweries, Ceytaş delivers tailored tank solutions across industries.

Tank and Agitator Integration

Supplying both tanks and agitators, Ceytaş partners with top agitator manufacturers to ensure seamless integration and reliable, process-specific performance.

Heating & Cooling Solutions

They offer complete thermal control for processes like pasteurization and fermentation, including:

-

Dimple jackets

-

Double-wall tanks

-

Half-pipe coil systems

Insulation with stainless steel cladding ensures products reach and maintain target temperatures on time.

POWDER & LIQUID

FERTILIZER

PRODUCTION LINEs

They also specialize in the design and manufacture of advanced NPK production lines for powder fertilizers, featuring precise dosing, efficient blending, and seamless filling systems. Constructed primarily from high-grade stainless steel, their NPK production lines are engineered to meet the rigorous demands of the fertilizer industry. These systems ensure optimal performance, reliability, and quality from initial consultation to final installation, providing a comprehensive solution for fertilizer production needs.

STAINLESS STEEL

STEAM STERILIZERS

They also specialize in producing high-quality vertical steam sterilizers designed for efficient and reliable sterilization of various raw materials. Engineered to meet the highest standards of safety and performance, these sterilizers ensure thorough sterilization using pressurized steam. Built with durable materials and advanced technology, their vertical steam sterilizers offer user-friendly controls, precise temperature management, and energy-efficient operation.

STAINLESS STEEL

VACUUM

EVAPORATORS

They design and manufacture a wide range of high-performance evaporators, including falling film evaporators under vacuum, rising film evaporators, and other specialized types. Crafted from premium stainless steel, their evaporators are tailored to meet the diverse needs of various industries. From chemical processing to food production, their equipment ensures efficient, reliable, and high-quality evaporation processes, providing robust solutions from initial consultation to final installation.

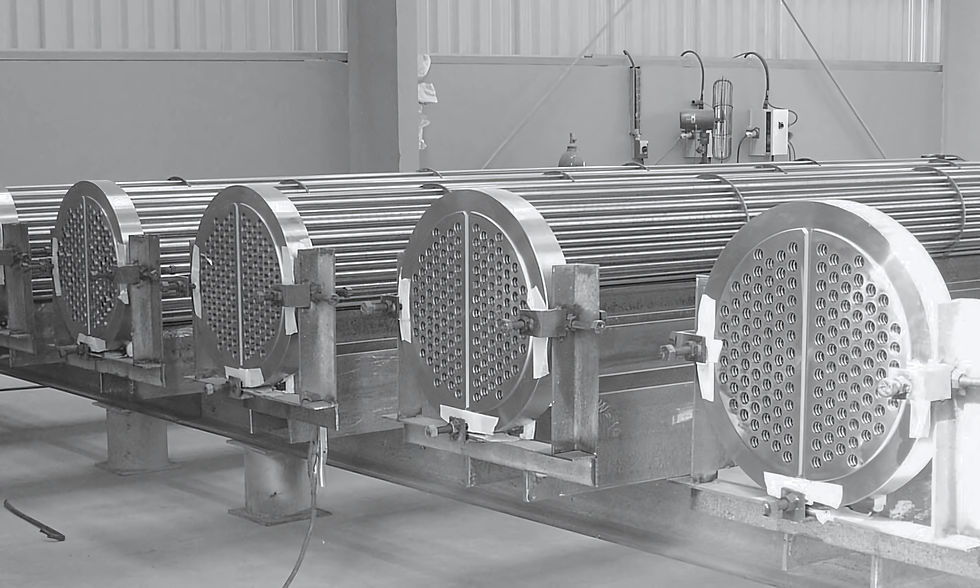

STAINLESS STEEL

HEAT EXCHANGERS

At Ceytaş, they are dedicated to designing and manufacturing premium stainless steel heat exchangers for diverse industries, including chemical processing, food production, pharmaceuticals, and HVAC. Their product range includes shell and tube, plate, air-cooled, and double pipe heat exchangers, all meticulously engineered to meet specific application requirements, ensuring exceptional performance and reliability.

CNC BRIDGE SAW CUTTING

MACHINES - 3X / 4X / 5X

They offer CNC bridge saw cutting machines (3X/4X/5X, 2100x3500 mm) with hydraulic lifting tables, featuring powerful servo motors on X, Y, C, and A axes, capable of cutting kitchen countertops, geometric shapes, and profiles using DXF files, with 3D and 5D engraving, automatic tool change, high-resolution industrial camera for vein tracking, vacuum transport, saw diameter and stone thickness sensors, and a simulation module for real-time cutting previews.

CNC SIDE SAW CUTTING

MACHINES

They offer CNC side saw cutting machines with a strong 240 NPU sub-chassis and a 2000x3100 mm cutting table, featuring a specially designed arm and main body for more precise cuts with less table trimming thanks to electronic height measurement via encoders on X, Y, and Z axes; automatic cuts with five presets in both longitudinal and transverse directions; PLC-controlled automation with a 10-inch touchscreen; motor control with inverters on X, Y, and Z axes; safety sensors on all axes; backlash-free table and head movement with backlash-free reducers; auto table trimming/machining programs; automatic water valve; closed slide oil system rails; and an upper arm with bellows closure. Optional features include servo motor head rotation for 4-direction 45° cutting and hydraulic table tilting.